Mostrar el registro sencillo del ítem

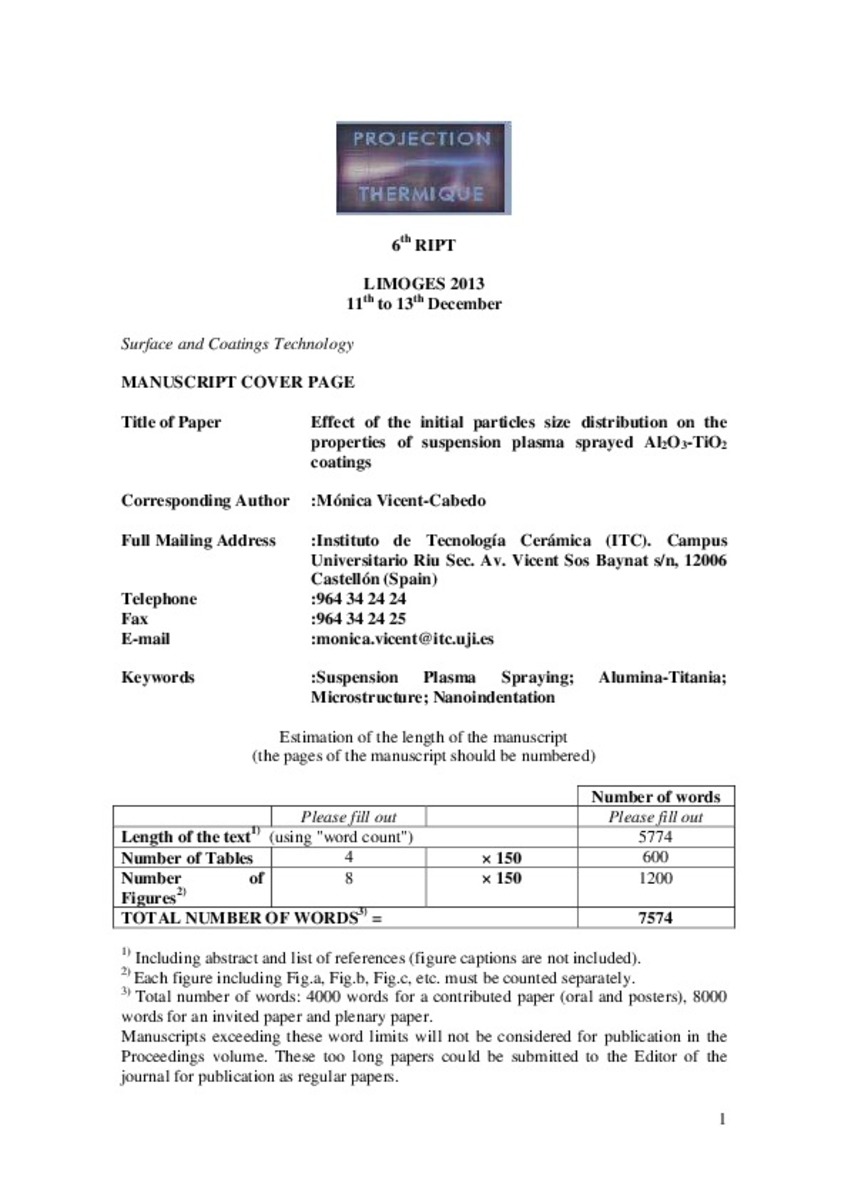

Effect of the initial particle size distribution on the properties of suspension plasma sprayed Al2O3-TiO2 coatings

| dc.contributor.author | Vicent Cabedo, Mónica | |

| dc.contributor.author | Bannier, Emilie | |

| dc.contributor.author | Carpio Cobo, Pablo | |

| dc.contributor.author | Rayón, E. | |

| dc.contributor.author | Benavente, Rut | |

| dc.contributor.author | Salvador Moya, María Dolores | |

| dc.contributor.author | Sánchez-Vilches, Enrique | |

| dc.date.accessioned | 2016-03-14T11:47:05Z | |

| dc.date.available | 2016-03-14T11:47:05Z | |

| dc.date.issued | 2015-04 | |

| dc.identifier.citation | VICENT, M., et al. Effect of the initial particle size distribution on the properties of suspension plasma sprayed Al 2 O 3–TiO 2 coatings. Surface and Coatings Technology, 2015, vol. 268, p. 209-215. | ca_CA |

| dc.identifier.uri | http://hdl.handle.net/10234/153631 | |

| dc.description.abstract | Al2O3–TiO2 coatings have been deposited by atmospheric plasma spraying from agglomerated, nanostructured powders showing better properties than those of their conventional (microstructured) counterparts. These nanostructured coatings can be also obtained by suspension plasma spraying however the research on suspension plasma sprayed Al2O3–TiO2 is still scarce. Consequently, it is crucial to study the effect of the suspension characteristics on the coating properties and to optimize the deposition process. In this work, Al2O3–13 wt.% TiO2 tribological coatings were successfully deposited by suspension plasma spraying from three different feedstocks: a nanometric suspension and two bimodal suspensions with different solid contents made up of titania nanoparticles and alumina submicron-sized particles. The coating microstructure and phase composition were characterized using scanning electron microscopy and X-ray diffraction analysis. Moreover, nanoindentation technique was used to determine the nanomechanical properties of coatings. The influence of the feed suspension characteristics on the final coating quality was analyzed. Findings showed that similar microstructures and phases were developed after depositing the different feedstocks. In addition suspension feedstock made up of nanoparticles resulted in a coating with better mechanical properties. However the use of submicron-sized particles in the suspension feedstocks gives rise to some technical and economic advantages in the process which should be taken into account when a suspension plasma spraying process is to be set up. | ca_CA |

| dc.format.extent | 6 p. | ca_CA |

| dc.format.mimetype | application/pdf | ca_CA |

| dc.language.iso | eng | ca_CA |

| dc.publisher | Elsevier | ca_CA |

| dc.relation.isPartOf | Surface and Coatings Technology Volume 268, 25 April 2015 | ca_CA |

| dc.rights | Copyright © 2014 Elsevier B.V. All rights reserved. | ca_CA |

| dc.rights | Atribución-NoComercial-SinDerivadas 4.0 España | |

| dc.rights.uri | http://creativecommons.org/licenses/by-nc-nd/4.0/ | |

| dc.subject | Suspension plasma spraying | ca_CA |

| dc.subject | Alumina–titania | ca_CA |

| dc.subject | Microstructure | ca_CA |

| dc.subject | Nanoindentation | ca_CA |

| dc.title | Effect of the initial particle size distribution on the properties of suspension plasma sprayed Al2O3-TiO2 coatings | ca_CA |

| dc.type | info:eu-repo/semantics/article | ca_CA |

| dc.identifier.doi | http://dx.doi.org/10.1016/j.surfcoat.2014.12.010 | |

| dc.rights.accessRights | info:eu-repo/semantics/openAccess | ca_CA |

| dc.relation.publisherVersion | http://www.sciencedirect.com/science/article/pii/S0257897214011426 | ca_CA |

| dc.type.version | info:eu-repo/semantics/acceptedVersion |

Ficheros en el ítem

Este ítem aparece en la(s) siguiente(s) colección(ones)

-

QUI_Articles [296]